Job openings at Department of Solid Waste Management

Department of Solid Waste Management is looking for solid waste management professionals to fill job openings. If you're interested, apply online. The benefits and salary offered by this agency are competitive. The benefits include vision, dental, and medical insurance. There is also life insurance and short-term disabilities insurance. Stock purchase plans, company matches and 401K accounts also available. Company also offers personal days.

Locations of facilities

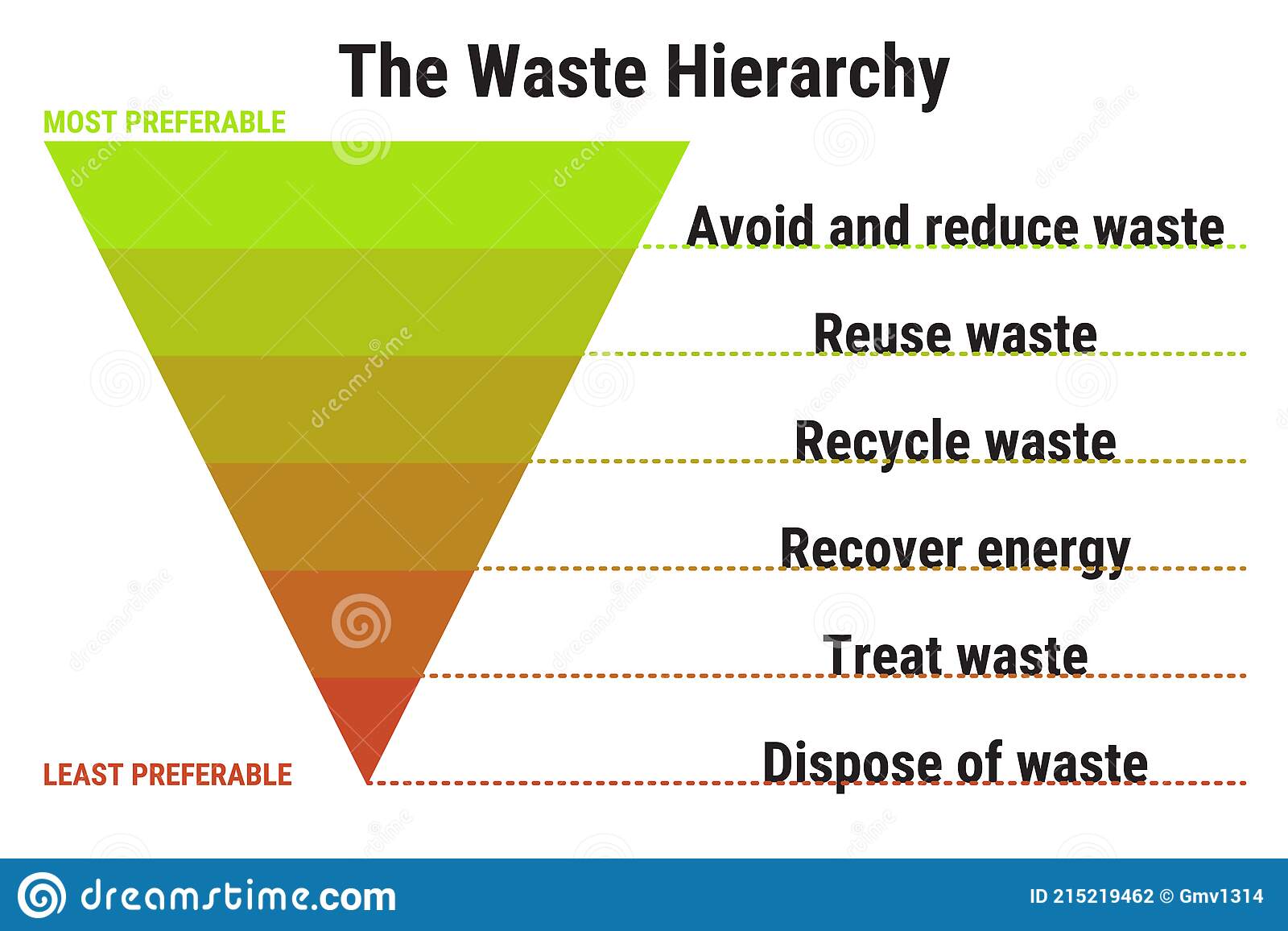

The Department of Solid Waste Management of Miami-Dade County offers various services for the community. These services include bulk trash collection, recycling and garbage collection. The Department is home to one of the most extensive government-owned waste collection systems within the Southeast United States. They also own one of Europe's most technologically advanced energy-to-waste facilities. Services range from residential trash collection to commercial recycling.

Miami, Florida's facilities include Covanta’s facility for waste-to–energy, which was operational since 1985. The facility is managed by the Miami-Dade County. Recently, the county approved a Fourth Amended and Restated Operations and Management Agreement. The County has also expressed an interest in building a new facility with a mass-burn combustion process, and the preliminary cost estimate is $900 million to $1 billion.

Recycling rates are high in Miami-Dade County

The county's recycling rate is 18%. This county uses a formula that adds up two types of recyclable material. A low rate of curbside recycling can be attributed to contamination. Florida's largest source for recycled material comes from commercial waste. Miami-Dade doesn't collect commercial waste so it is not required by law to report the recycling numbers to Florida.

Compology, which provides camera-based meters, has recently joined the city to increase recycling rates for Miami-Dade County. This partnership will see cameras installed in recycling bins and waste containers. This will allow city officials to track the type and amount of recyclable materials.

Services cost

Waste management in Miami is a competitive business. There is no government-regulated price for waste disposal and haulers charge what they want to collect your waste. Local recycling programs offer businesses the opportunity to cut down on waste volume and reduce costs. Compiling recyclables can reduce hauling costs and help businesses save money.

The Department of Solid Waste Management in Miami-Dade County has noticed its costs rising and has decided to raise customer fees. The proposed fee increase will add $25 to the annual cost of household bills, which is approximately $2.08 per person. However, the fee increase proposed won't cover projected deficits in department's $350million operational budget. Additional subsidies will be required in coming years.

FAQ

Why is it important that companies use project management methods?

Project management techniques ensure that projects run smoothly while meeting deadlines.

This is because most businesses rely on project work for their products and services.

Companies must manage these projects effectively and efficiently.

Companies may lose their reputation, time and money if they do not have effective project management.

What is the meaning of "project management?"

We mean managing the activities involved in carrying out a project.

We help you define the scope of your project, identify the requirements, prepare the budget, organize the team, plan the work, monitor progress and evaluate the results before closing down the project.

What is Kaizen?

Kaizen is a Japanese term which means "continuous improvement." This philosophy encourages employees to continually look for ways to improve the work environment.

Kaizen is based upon the belief that each person should be capable of doing his or her job well.

Statistics

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

How does Lean Manufacturing work?

Lean Manufacturing techniques are used to reduce waste while increasing efficiency by using structured methods. These processes were created by Toyota Motor Corporation, Japan in the 1980s. The primary goal was to make products with lower costs and maintain high quality. Lean manufacturing is about eliminating redundant steps and activities from the manufacturing process. It is composed of five fundamental elements: continuous improvement; pull systems, continuous improvements, just-in–time, kaizen, continuous change, and 5S. Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement is the continuous improvement of existing processes. Just-in-time is when components and other materials are delivered at their destination in a timely manner. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. To achieve the best results, these five elements must be used together.

Lean Production System

Six key concepts are the basis of lean production:

-

Flow is about moving material and information as near as customers can.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban - use visual signals such as colored tape, stickers, or other visual cues to keep track of inventory;

-

Theory of constraints - identify bottlenecks during the process and eliminate them with lean tools like Kanban boards.

-

Just-in Time - Send components and material directly to the point-of-use;

-

Continuous improvement - make incremental improvements to the process rather than overhauling it all at once.